The demand for Aluminium Scaffolding for Sale in Saudi Arabia has been steadily increasing as industries seek safer, lighter, and more efficient access solutions. Construction, industrial maintenance, and infrastructure projects across the Kingdom are embracing aluminium scaffolding due to its superior strength-to-weight ratio, corrosion resistance, and adaptability. From large-scale commercial developments to small renovation projects, aluminium scaffolding is now viewed as an indispensable tool that combines performance, safety, and convenience.

Why Aluminium Scaffolding is the Preferred Choice?

Aluminium scaffolding stands apart from traditional steel systems due to its unique blend of properties. Its lightweight nature allows for faster assembly and dismantling, making it highly suitable for projects where mobility and time efficiency are crucial. In addition, the natural corrosion resistance of aluminium ensures a longer lifespan, even in challenging environmental conditions like those found in Saudi Arabia.

Key advantages include:

Lightweight construction: Easy to handle, transport, and reposition.

Corrosion-resistant: Ideal for harsh weather and outdoor work environments.

High load-bearing strength: Despite its low weight, it can support significant loads.

Quick assembly: Reduces downtime and improves workflow efficiency.

Low maintenance: Requires minimal upkeep, cutting long-term operational costs.

These characteristics make aluminium scaffolding particularly valuable in industries where time, safety, and cost management are top priorities.

The Rise of Aluminium Scaffolding in Saudi Arabia

Saudi Arabia’s construction sector is undergoing rapid transformation driven by Vision 2030, which focuses on large infrastructure, tourism, and commercial developments. Projects such as NEOM, The Red Sea Project, and Qiddiya are setting new benchmarks for architectural innovation and efficiency. As these ventures progress, the need for safe and flexible access systems becomes increasingly critical—hence, aluminium scaffolding has become a go-to solution.

Unlike heavy steel systems that require mechanical lifting or more manpower, aluminium scaffolds can be easily transported and set up by fewer workers. This efficiency not only saves labor costs but also reduces fatigue-related risks on construction sites. The result is a safer, faster, and more productive working environment that aligns perfectly with the evolving construction standards across the Kingdom.

Common Applications of Aluminium Scaffolding

Aluminium scaffolding’s versatility allows it to serve multiple industries and functions. Its modular structure can be configured for various project needs—whether vertical access, maintenance platforms, or mobile towers.

1. Construction and Building Maintenance

In construction, aluminium scaffolding is used for painting, plastering, electrical installations, and façade work. It provides stable access for workers at varying heights while minimizing setup time.

2. Industrial Facilities and Warehouses

Maintenance of industrial plants, oil refineries, and warehouse operations often requires access to elevated areas. Aluminium scaffolding ensures safe reach while withstanding exposure to chemicals and heat.

3. Event Management and Stage Setup

Event organizers and lighting technicians prefer aluminium scaffolds for stage construction, lighting rigs, and camera platforms. Their portability and quick setup make them ideal for time-sensitive projects.

4. Residential Use and Interior Renovations

Smaller, mobile aluminium scaffolding towers are popular for residential painting, ceiling repairs, and interior maintenance. Their compact design allows easy movement through doorways and tight spaces.

5. Facility Cleaning and Inspections

Airports, malls, and hotels use aluminium scaffolds for cleaning glass façades, inspecting ceilings, and maintaining HVAC systems. The system’s stability ensures worker safety while providing extended reach.

Types of Aluminium Scaffolding Available

Aluminium scaffolding systems are available in several configurations to match different site requirements. Each type offers specific advantages based on the scope of work and environment.

1. Single Width Towers

Designed for narrow spaces, these are perfect for indoor work where mobility and space-saving are crucial.

2. Double Width Towers

Offer greater stability and workspace, suitable for larger projects like façade repairs or plastering.

3. Folding Scaffolding

Highly portable and easy to store, folding systems are commonly used for short-duration maintenance tasks.

4. Mobile Scaffolding

Equipped with wheels, this type allows workers to move between work areas without disassembly, improving project efficiency.

5. Cantilever Scaffolding

Used when work areas are hard to reach or when access from the ground is obstructed. Ideal for façade or bridge maintenance.

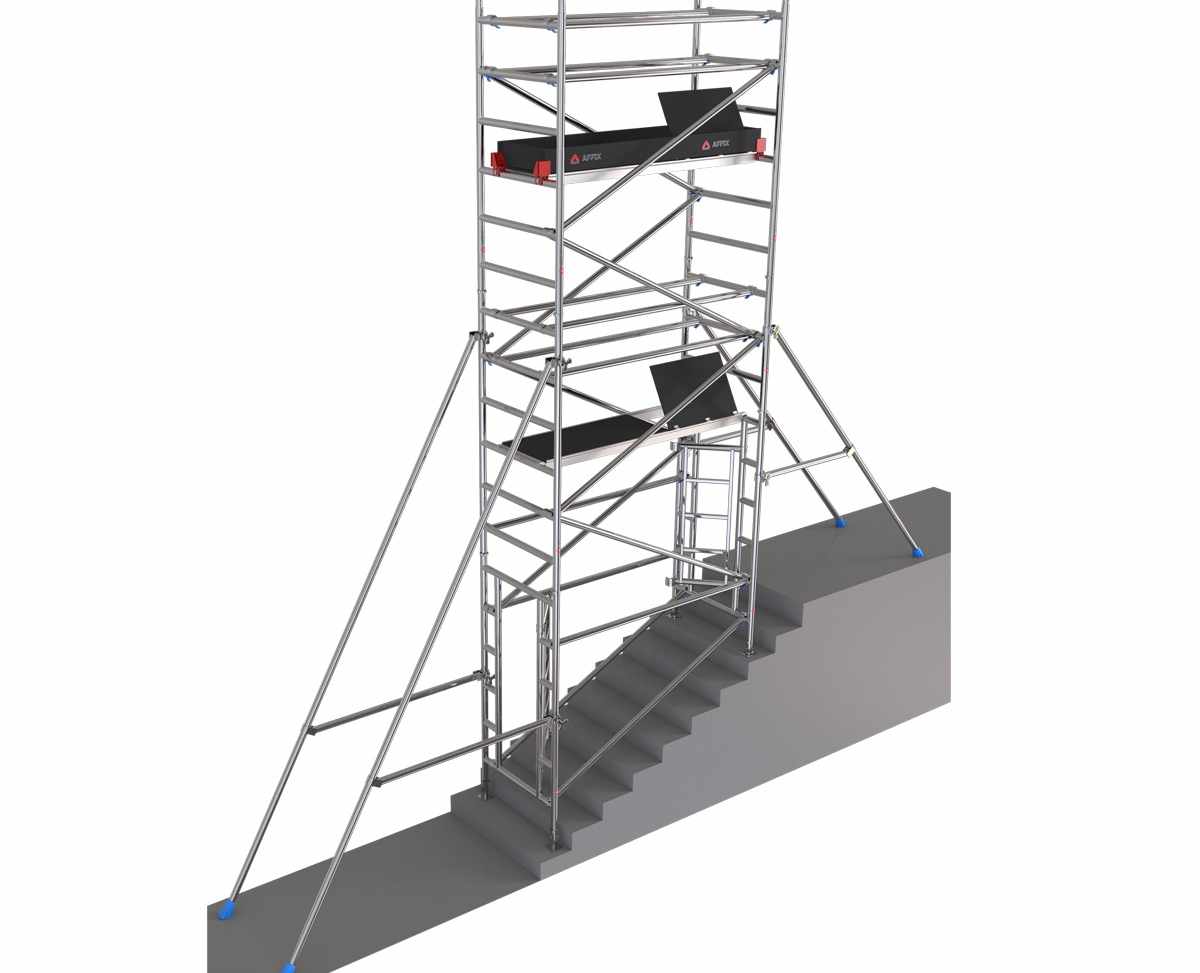

6. Stairway Scaffolding Towers

Include built-in staircases, offering secure access between levels—often used in industrial or high-rise applications.

Each type can be customized in terms of height, platform dimensions, and safety accessories depending on the nature of the project.

Key Features That Define Quality Aluminium Scaffolding

Selecting high-quality scaffolding is essential to ensure worker safety and long-term value. When evaluating aluminium scaffolding, several design and safety features play a crucial role:

T6-grade aluminium: Offers maximum strength and durability for heavy-duty use.

Slip-resistant platforms: Prevent accidents in wet or dusty conditions.

Lockable caster wheels: Provide stability during stationary work.

Guardrails and toe boards: Enhance safety for workers at height.

Interlocking frames: Ensure quick, secure assembly without specialized tools.

Adjustable height systems: Allow flexibility across various project requirements.

These features not only improve usability but also align with international safety standards such as EN1004 and ANSI.

Benefits of Using Aluminium Scaffolding in Saudi Projects

Saudi Arabia’s diverse climatic and industrial conditions make aluminium scaffolding particularly advantageous. From scorching heat to high humidity near coastal zones, aluminium structures perform exceptionally well compared to traditional alternatives.

Durability in Harsh Conditions

Aluminium does not rust, which means it remains structurally sound even in high-salinity or humid environments.

Reduced Transportation Costs

Lightweight components mean easier logistics and lower fuel costs when moving between sites.

Improved Worker Safety

Slip-resistant steps, guardrails, and secure joints minimize fall risks, meeting local and international safety norms.

Eco-Friendly Material

Aluminium is 100% recyclable, supporting sustainable building practices promoted under Vision 2030.

Faster Setup Times

Quick installation reduces project delays and enhances site productivity, crucial for large-scale developments.

Safety Regulations and Standards in Saudi Arabia

Scaffolding operations in Saudi Arabia are governed by safety standards and building regulations that prioritize worker welfare. The Ministry of Municipal and Rural Affairs and Housing, along with the Saudi Standards, Metrology and Quality Organization (SASO), enforce guidelines covering scaffold design, inspection, and usage.

Key safety protocols include:

Periodic inspection: Scaffolds must be inspected before use and after any structural change.

Load limitations: Maximum allowable loads should never be exceeded.

Fall protection: Guardrails, harnesses, and toe boards are mandatory at elevated levels.

Qualified supervision: Only trained personnel should assemble or dismantle scaffolds.

Stable foundations: Platforms must rest on firm, level surfaces to prevent tilting.

These regulations help maintain high safety benchmarks across construction and industrial sites throughout the Kingdom.

Comparing Aluminium Scaffolding with Steel Scaffolding

FeatureAluminium ScaffoldingSteel ScaffoldingWeightExtremely lightweightHeavy and difficult to moveCorrosion ResistanceExcellentProne to rustSetup TimeFast and efficientTime-consumingMaintenanceMinimalRequires frequent upkeepLoad CapacityHigh for its weightVery high but adds bulkCost EfficiencyLong-term savingsHigher long-term costsMobilityEasy to transportRequires machinery for movement

The comparison highlights why aluminium scaffolding is becoming the preferred choice across construction, manufacturing, and facility management sectors in Saudi Arabia.

Factors to Consider Before Buying Aluminium Scaffolding

Choosing the right aluminium scaffolding requires evaluating several factors related to safety, application, and budget.

1. Project Requirements

Assess the type of work—painting, façade work, electrical installations—to determine whether a single-width, double-width, or mobile tower suits best.

2. Load Capacity

Ensure the scaffold can handle the weight of workers, tools, and materials safely.

3. Height and Reach

Consider maximum working height and whether extension modules are required.

4. Safety Features

Check for guardrails, stabilizers, and anti-slip platforms that meet safety standards.

5. Ease of Assembly

Quick-locking joints and modular designs make setup faster and safer.

6. Maintenance Requirements

Opt for designs with minimal maintenance needs for long-term efficiency.

7. Certification

Ensure compliance with EN1004 or equivalent standards to guarantee product safety and quality.

These considerations can significantly impact overall performance, safety, and cost-effectiveness of your investment.

Maintenance Tips for Longevity

Proper maintenance ensures the durability and safety of aluminium scaffolding. Though low-maintenance by nature, a few best practices can extend its service life:

Regular Inspection: Check joints, locks, and platforms for wear or deformation.

Cleaning: Remove dust, debris, or concrete residue to prevent slippage.

Storage: Keep scaffolding in a dry area when not in use to avoid corrosion on accessories.

Lubrication: Apply light oil to wheels and locking pins periodically.

Replace Damaged Parts: Never use defective or bent components; always replace them promptly.

Routine care helps maintain optimal performance and ensures compliance with safety standards.

The Future of Aluminium Scaffolding in Saudi Arabia

As Saudi Arabia continues to diversify its economy through construction and industrial expansion, the demand for efficient access solutions will grow. Aluminium scaffolding aligns perfectly with this progress—offering sustainability, adaptability, and safety. With the rise of modular and mobile systems, it’s becoming easier to deploy scaffolds across various sectors, from construction to entertainment and maintenance.

The shift toward automation and advanced building technologies also favors lightweight, flexible solutions like aluminium scaffolding. As more projects emphasize worker safety, productivity, and eco-friendly practices, the adoption of aluminium scaffolding is expected to strengthen further in the Kingdom.

Conclusion

The surge in infrastructure and construction projects has amplified the importance of reliable access systems. Aluminium Scaffolding for Sale in Saudi Arabia provides the perfect balance of safety, convenience, and durability required by modern industries. Its lightweight design, corrosion resistance, and easy mobility make it a superior alternative to traditional materials, ensuring efficiency without compromising on safety.

Whether for large commercial construction, maintenance operations, or event setups, aluminium scaffolding delivers consistent performance that meets the evolving standards of the Saudi market. With proper selection, maintenance, and compliance with safety regulations, it remains one of the most effective tools for achieving precision and safety in elevated work environments.

Write a comment ...